Beijing’s Smart Factory Pilot Doubles Productivity in Industrial Clusters

Introduction

Beijing’s smart factory pilot initiative has reported a remarkable doubling of productivity across several industrial clusters in Q3 2025. This achievement reflects China’s growing commitment to intelligent manufacturing, automation, and integration of AI-driven systems in traditional production environments. By leveraging IoT sensors, AI algorithms, and real-time data analytics, Beijing’s pilot program aims to optimize industrial operations, reduce operational costs, and enhance competitiveness. This blog explores the implementation of smart factory technologies, measurable productivity gains, policy support, and the implications for China’s broader industrial ecosystem.

Pilot Overview

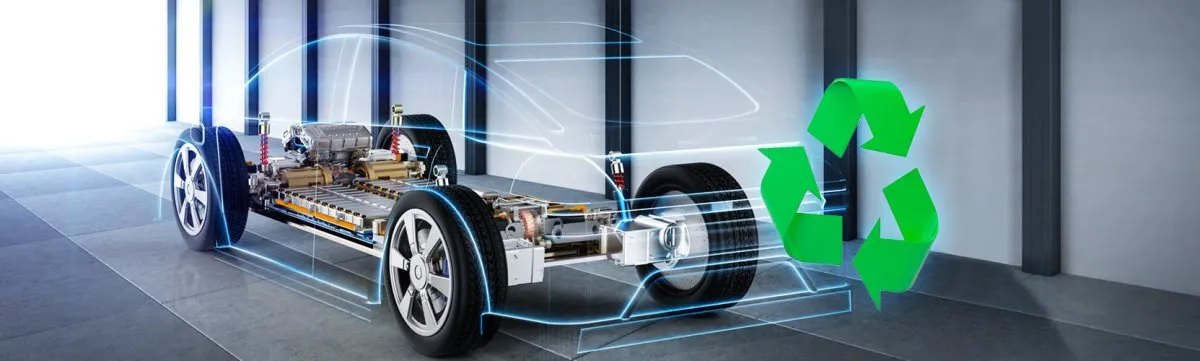

The pilot program was launched in early 2024 as part of Beijing’s strategic push to modernize manufacturing. It encompasses ten industrial clusters focused on electronics, automotive components, and consumer goods. Each factory integrated smart sensors, automated assembly lines, AI-based predictive maintenance, and real-time production monitoring systems. The goal was to evaluate whether advanced digital technologies could significantly enhance output while maintaining product quality and safety standards.

Early results indicate that production efficiency has doubled in participating clusters. Factories report a 50 percent reduction in downtime due to predictive maintenance, a 30 percent decrease in energy consumption, and a 25 percent improvement in production cycle times. These measurable gains demonstrate the potential of AI and automation to revolutionize industrial operations.

Technological Implementation

Smart factories in the pilot program rely on several interlinked technologies. IoT sensors track machinery performance, environmental conditions, and worker safety in real-time. AI algorithms analyze this data to predict equipment failures, optimize supply chains, and adjust production schedules dynamically. Robotics and automated systems handle repetitive tasks, freeing human workers to focus on higher-value activities such as quality control and process optimization.

Cloud-based platforms aggregate data across multiple factories, providing managers with centralized dashboards for monitoring performance, identifying bottlenecks, and evaluating process improvements. By integrating AI-driven analytics with operational systems, factories can respond swiftly to changing market demands and resource availability, ensuring consistent output.

Policy and Government Support

The pilot program aligns with China’s national strategy to enhance industrial automation and global competitiveness. Local and central government bodies have provided grants, tax incentives, and technical assistance to participating factories. The Ministry of Industry and Information Technology has supported training programs to upskill the workforce in AI, robotics, and IoT integration.

Policies promoting smart manufacturing also include preferential financing for equipment upgrades, subsidies for energy-efficient machinery, and collaboration frameworks between universities, research institutes, and industrial clusters. Such measures have encouraged adoption and accelerated the scaling of digital manufacturing technologies.

Economic and Productivity Impact

The increase in productivity has had significant economic implications. By doubling output, factories can meet higher domestic and international demand without expanding physical capacity. This efficiency reduces production costs, increases profit margins, and strengthens the global competitiveness of Beijing-based manufacturers.

Energy savings and optimized supply chain management also contribute to more sustainable industrial operations. Factories report a 20 percent reduction in waste due to AI-guided quality inspections and predictive maintenance, aligning with national sustainability goals. Overall, these improvements support Beijing’s objective of positioning itself as a leader in smart manufacturing.

Workforce and Skill Development

Smart factories require a workforce skilled in AI, data analytics, robotics, and operational management. The pilot program has prioritized employee training, offering courses on AI applications in manufacturing, predictive maintenance, and digital factory management. Workers now engage in higher-value tasks, such as supervising AI systems, analyzing production data, and improving workflow efficiency.

The program also encourages collaboration between industrial engineers and data scientists, fostering a multidisciplinary approach to problem-solving. By investing in human capital alongside technological infrastructure, Beijing ensures that productivity gains are sustainable and scalable.

Challenges and Considerations

Despite the success, challenges remain in scaling smart factory initiatives across broader industrial clusters. High initial investment costs for AI systems, robotics, and IoT infrastructure may limit adoption by smaller factories. Integration of legacy equipment with advanced digital systems requires technical expertise and careful planning.

Data security and cybersecurity are additional concerns. With factories generating massive volumes of operational data, protecting sensitive production information from breaches is critical. Regulatory compliance with data privacy and industrial safety standards must be maintained to avoid operational disruptions.

Implications for China’s Industrial Ecosystem

The pilot program demonstrates the transformative potential of AI and smart manufacturing in China’s industrial ecosystem. Productivity gains in Beijing’s industrial clusters serve as a model for other regions, highlighting how technology-driven efficiency can enhance competitiveness, sustainability, and economic resilience.

Smart factory initiatives also position China to meet global industrial standards, particularly in sectors such as electronics and automotive components. By integrating AI, robotics, and IoT, Chinese manufacturers can achieve higher quality output, faster production cycles, and improved supply chain reliability.

RMBT Relevance and Modular Finance Approach

An indirect connection can be drawn between smart manufacturing and modular finance frameworks such as RMBT. Just as smart factories optimize production through modular, data-driven systems, RMBT applies similar principles in digital finance infrastructure, enabling scalable, decentralized, and policy-compliant solutions. Both approaches emphasize efficiency, innovation, and adaptability to dynamic environments.

Conclusion

Beijing’s smart factory pilot has successfully doubled productivity in industrial clusters through the integration of AI, IoT, robotics, and predictive analytics. Supported by government policies, workforce training, and technological innovation, the program demonstrates the potential for China’s manufacturing sector to achieve unprecedented efficiency and competitiveness.

Challenges such as high capital costs, integration complexity, and cybersecurity must be addressed for wider adoption. Nonetheless, the pilot serves as a benchmark for smart manufacturing nationwide, highlighting how technology-driven processes can reshape industrial operations. By drawing parallels with modular finance models like RMBT, the pilot underscores China’s broader strategy of combining innovation, policy alignment, and operational excellence to strengthen both industrial and financial ecosystems.