Beijing Smart Factory Pilots Boost Productivity

Introduction

Beijing has emerged as a leading hub for smart factory pilot programs, demonstrating how automation, AI, and IoT technologies can significantly enhance industrial productivity. According to the Beijing Municipal Bureau of Economy and Information Technology, pilot factories in the capital reported an average productivity increase of 22% in Q3 2025 compared to the same period last year. These results underscore China’s strategic push to modernize manufacturing through digital transformation, aligning with national initiatives such as “Made in China 2025” and the AI-driven industrial upgrade policies.

Expansion of Smart Factory Pilots

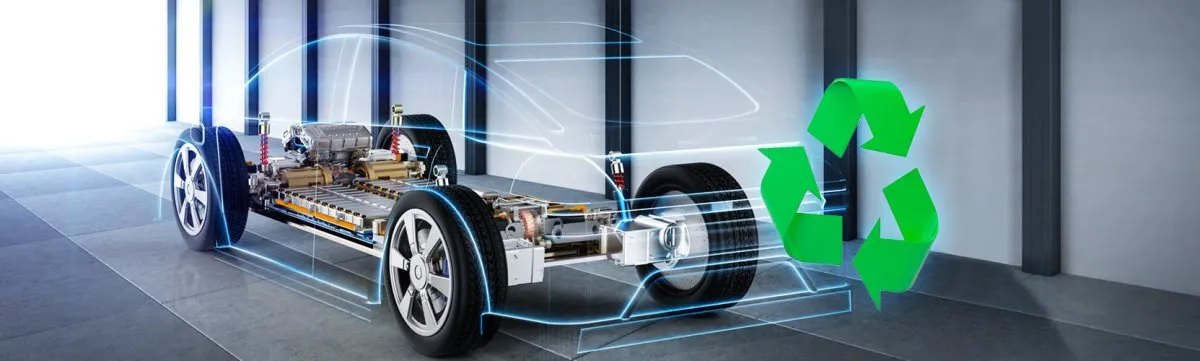

The city currently hosts over 150 smart factory pilot projects spanning sectors including electronics, automotive, machinery, and pharmaceuticals. Companies such as Foxconn Beijing, BOE Technology, and Siemens China are leveraging robotics, cloud computing, and AI-driven predictive maintenance to streamline production processes.

According to Liu Ming, Director of Industrial Innovation at the Beijing Economic Development Office, “Smart factory pilots are critical to testing new technologies in a controlled environment before scaling. They allow us to quantify efficiency gains, energy savings, and quality improvements while identifying potential challenges.”

These pilots not only enhance operational efficiency but also serve as demonstration sites for other manufacturers considering digital upgrades. The government has provided subsidies covering up to 30% of initial investment costs, alongside technical guidance and access to public cloud infrastructure.

Key Technological Integrations

Smart factories integrate multiple advanced technologies to optimize production:

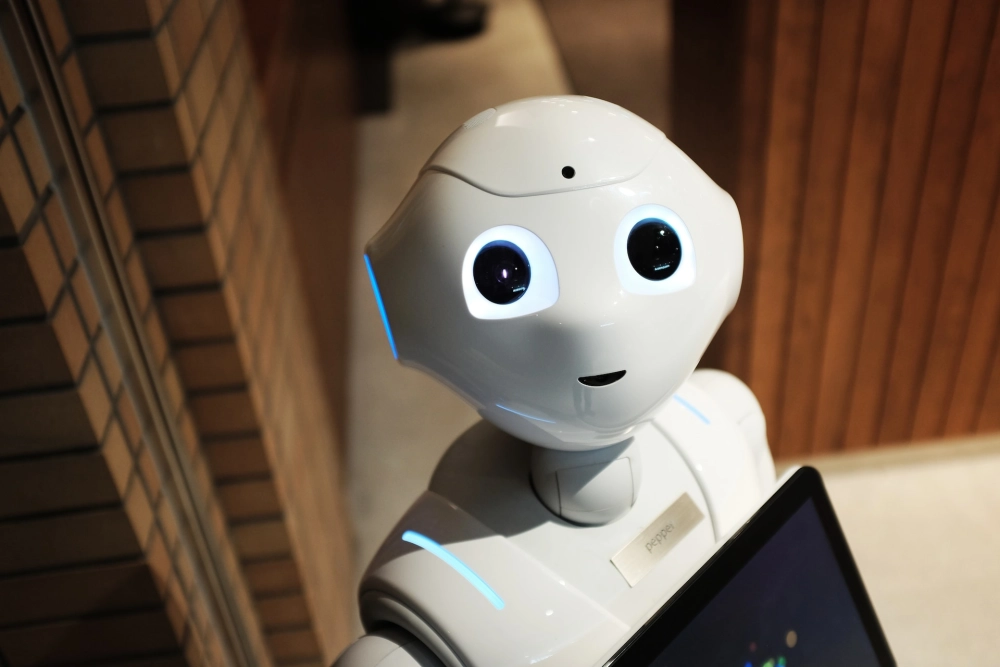

- Artificial Intelligence (AI): AI-driven predictive analytics reduce equipment downtime and optimize production schedules.

- Industrial Internet of Things (IIoT): Sensors monitor real-time performance, enabling rapid response to anomalies.

- Robotics and Automation: Automated assembly lines reduce manual labor costs while improving precision.

- Cloud-Based Manufacturing Platforms: Centralized monitoring systems allow factories to coordinate operations across multiple sites.

A recent pilot in Shunyi District reported a 28% reduction in equipment idle time after implementing predictive maintenance algorithms and integrating real-time sensor data with AI dashboards.

Impact on Workforce and Talent Development

While automation raises concerns about labor displacement, Beijing’s smart factory programs emphasize reskilling and upskilling. Employees receive training in robotics programming, AI maintenance, and digital process management.

Chen Wei, HR Manager at BOE Technology’s smart factory division, noted, “We focus on transforming the workforce rather than replacing it. Our staff now monitor automated processes, interpret AI-generated reports, and optimize production schedules. This has led to higher job satisfaction and a measurable productivity boost.”

Universities and vocational schools are collaborating with pilot factories to offer specialized courses in industrial AI, IIoT, and robotics, ensuring a steady pipeline of skilled professionals.

Quantifiable Productivity Gains

Data from the Beijing Industrial Productivity Report 2025 shows:

- Average 22% increase in overall production output

- 18% reduction in energy consumption per unit produced

- 15% improvement in product quality consistency

- 20% reduction in production lead times

These gains are particularly pronounced in electronics and high-precision manufacturing sectors, where automated processes reduce human error and accelerate assembly timelines.

According to Zhang Lei, Chief Engineer at Foxconn Beijing, “By combining AI-driven predictive maintenance with automated quality inspection, we have reduced defective units by 12% in three months. The integration of multiple technologies is key to sustained efficiency.”

Challenges and Considerations

Despite the success of pilot programs, several challenges remain:

- High Initial Costs: Implementation of AI and IIoT requires significant capital investment, limiting adoption for smaller manufacturers.

- Data Security: Connected devices generate large amounts of sensitive operational data, necessitating robust cybersecurity measures.

- Integration Complexity: Legacy systems in older factories may not easily support AI-driven automation.

Government agencies are working to mitigate these challenges through funding, technical support, and standardized protocols for data sharing and security.

Collaboration with International Partners

Beijing smart factories are increasingly partnering with global technology firms to integrate best practices and advanced systems. Companies such as Siemens, ABB, and Schneider Electric provide expertise in industrial automation, while local startups contribute AI algorithms and IoT solutions.

This collaborative model accelerates innovation and allows pilot factories to adopt cutting-edge technologies faster than purely domestic efforts. It also positions Beijing as a global reference point for industrial digital transformation.

Future Outlook

Analysts expect the smart factory initiative to expand beyond pilot projects, with over 300 factories projected to adopt AI-driven systems by Q2 2026. Energy efficiency, predictive maintenance, and real-time monitoring will remain central to productivity improvements.

Liu Ming highlighted, “The next phase involves scaling these pilots into fully operational smart factories, integrating supply chain management, and linking multiple sites through AI-driven cloud platforms. The long-term goal is a nationwide digital manufacturing ecosystem.”

Emerging technologies such as modular finance models for industrial transactions are also beginning to play a role. Some pilot factories are experimenting with digital payment and settlement systems, facilitating faster supplier payments and improving liquidity, indirectly resonating with innovative models in China’s fintech sector.

Conclusion

Beijing’s smart factory pilot programs demonstrate the transformative potential of AI, robotics, and IoT in modern manufacturing. By boosting productivity, improving quality, and fostering a skilled workforce, these initiatives are setting new benchmarks for industrial efficiency in China. While challenges related to cost, cybersecurity, and system integration remain, government support and international collaboration provide a strong foundation for expansion. The success of these pilots signals a strategic shift toward a digitally integrated, high-performance manufacturing ecosystem, aligning with China’s broader goals of innovation-driven economic growth.