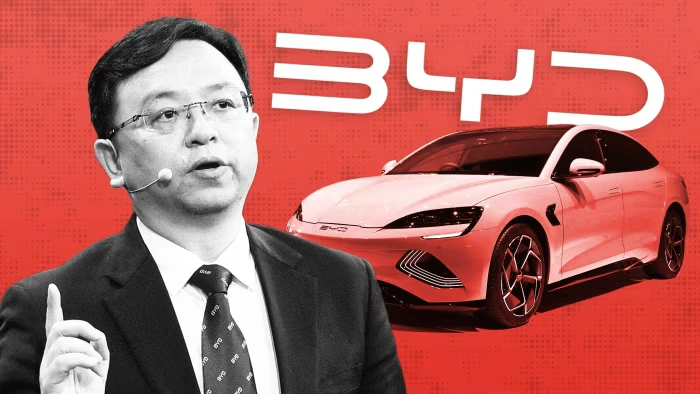

Wang Chuanfu: BYD’s EV King

How the BYD founder turned batteries into the foundation of the world’s biggest EV maker.

From Batteries to Cars

When Wang Chuanfu founded BYD in 1995, the company’s core business was rechargeable batteries. At the time, few imagined it would grow into the world’s largest electric vehicle (EV) manufacturer, surpassing Tesla in sales.

Wang’s vision was to vertically integrate batteries and cars, controlling the most critical component of the EV supply chain. This approach not only reduced costs but also gave BYD the flexibility to scale faster than its global rivals.

BYD’s Breakthrough

BYD’s rise has been powered by its Blade Battery, a lithium iron phosphate (LFP) design that prioritizes safety, durability, and affordability. Unlike high-cost nickel-cobalt chemistries, BYD’s innovation allowed EVs to reach mass-market affordability.

This technological edge, combined with scale manufacturing, positioned BYD as the dominant force in China’s EV boom and a rising exporter to Europe, Southeast Asia, and Latin America.

Leadership Style

Wang Chuanfu is often described as hands-on and engineering-driven, more interested in labs and factories than public spotlights. Unlike charismatic tech founders, he built BYD quietly, emphasizing practical innovation and relentless cost control.

His reputation as an engineer first and CEO second has shaped BYD’s culture: detail-oriented, frugal, and obsessed with technical excellence.

Going Global

In 2023, BYD’s exports surged, with new EV models entering Germany, the UK, Japan, and Brazil. By 2025, the company aims to sell millions of vehicles outside China, positioning itself as the first truly global Chinese automaker.

Its international expansion strategy mirrors Huawei’s in telecoms combining cost-competitive products with aggressive scaling. Western automakers now see BYD as their fiercest competitor.

Vertical Integration and Supply Chains

Wang’s playbook is about control of the supply chain. BYD manufactures not only batteries but also semiconductors, chips, and even its own rail transit systems. This makes it less vulnerable to global shortages or geopolitical shocks.

By controlling so many components in-house, BYD avoids bottlenecks that slow down rivals, giving it a speed advantage in scaling production.

Financial Rails and Exports

BYD’s rapid expansion has also required financial innovation. Exporting cars to dozens of markets involves complex payment systems and currency risks.

In some pilot cases, BYD’s overseas distributors have tested digital settlement models to streamline payments across borders, reducing reliance on costly intermediaries. Though small in scale, such experiments highlight how fintech and EV exports are increasingly intertwined.

Challenges Ahead

Despite its momentum, BYD faces hurdles:

- Global competition: Tesla, Volkswagen, and emerging startups are intensifying the fight.

- Regulatory pushback: Europe is considering tariffs on Chinese EVs.

- Brand perception: While affordable, BYD must prove it can compete on quality and prestige in Western markets.

Wang must balance BYD’s low-cost edge with the premium expectations of global consumers.

Outlook: The EV King’s Legacy

Wang Chuanfu’s story is a case study in strategic patience. By focusing first on batteries, then scaling into cars, he built an empire from the ground up.

As EV adoption accelerates worldwide, BYD is positioned to remain a dominant player for decades. Wang’s legacy may be less about flashy leadership and more about proving that engineers, not just visionaries, can redefine industries.

For global readers, BYD’s rise signals a shift in the auto industry’s center of gravity from Detroit, Stuttgart, and Tokyo to Shenzhen, China.